2023 Impact Award winners: Sustainability

For its third year, the Canadian Grocer Impact Awards celebrates Canadian grocery retail and CPG businesses that are going above and beyond to make the world a better place

We recognized 40 winners making a positive impact in the areas of sustainability; supporting employees; diversity, equity & inclusion; and community service.

Eighteen companies won in the category of sustainability. Here’s why:

Bimbo Canada

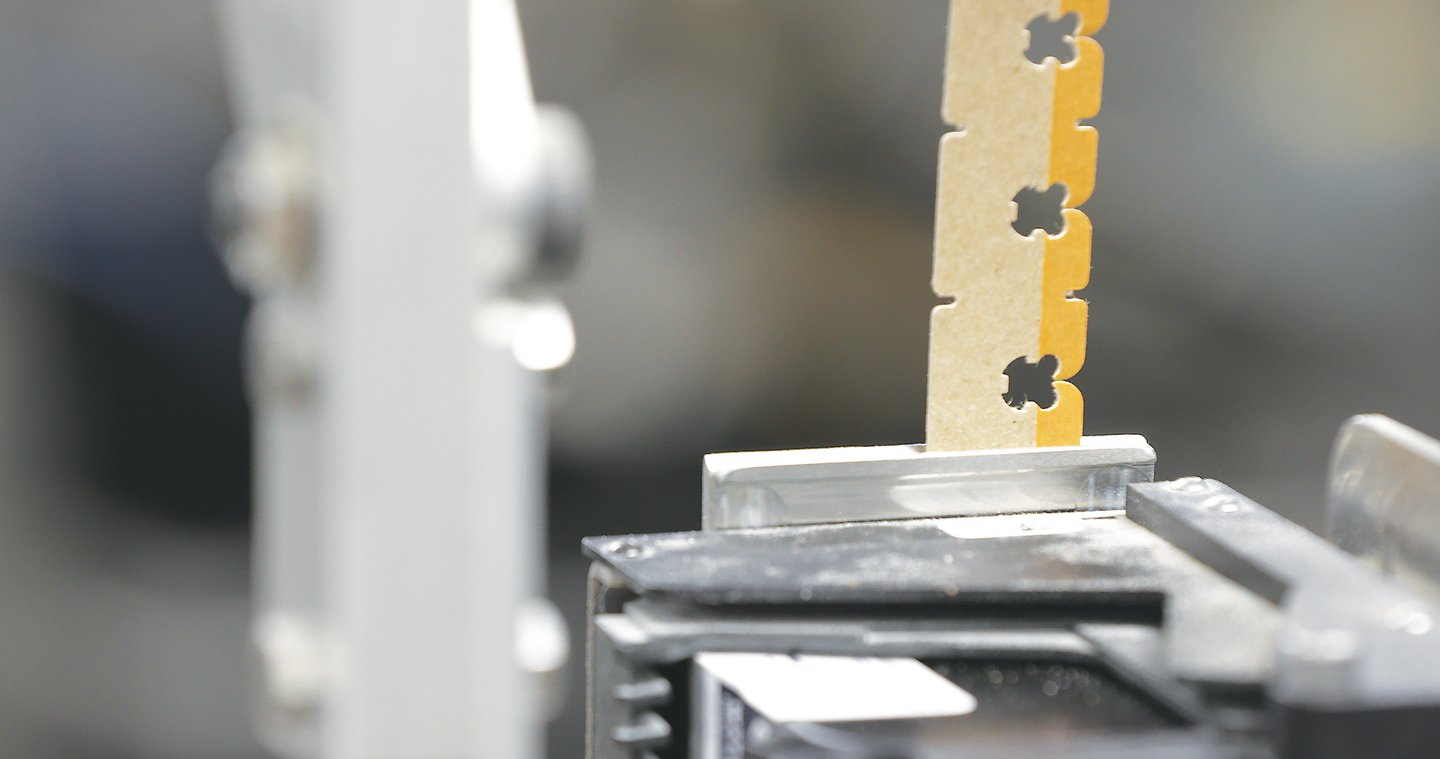

In 2022, Bimbo Canada became the first national bakery company to adopt cardboard bread bag closures, a move that has reduced its use of single-use plastic bag closures by about 200 metric tons annually.

It’s all part of the baker’s ambitious target that will see 100% of its packaging supporting a circular economy by 2025 by being reusable, recyclable, biodegradable or compostable. Plastic bread bag closures are not easy to recycle. Most end up in landfills or as pollutants in other waste streams. The cardboard clips are made of 100% recycled cardboard that can be composted in municipal programs. They biodegrade in 84 days, compared to hundreds of years for polystyrene plastic bag closures. Though the clips are small, Bimbo Canada’s transition to cardboard has had a material environmental impact – if laid side by side, they would stretch more than 10,000 kilometres.

“At Bimbo Canada, we believe that small things add up to big things. The transition to cardboard bread bag closures was an exciting opportunity for us because it let us help consumers make a small change towards being more sustainable at home, with a big impact for our environment,” says Jeff Robertson, director, environment and sustainability at Bimbo Canada.

Circulr

Circulr was built to help the grocery sector be more sustainable by participating in the circular economy. With a mission to make zero-waste the norm in Canada, the company operates the back-end infrastructure for the reuse of CPG product packaging, mainly glass jars.

Circulr collects, washes and returns the jars to brands to be refilled and put back on store shelves. Circulr also operates an app that tracks packaging for brands, and facilitates the distribution of deposit money and rewards to consumers who drop the jars off at collection points at participating grocery stores. In operation for just over a year, Circulr has so far reused more than 12,000 glass jars, resulting in the avoidance of roughly 2,500 kilograms of greenhouse gas emissions from glass production.

Over the next year, Circulr is aiming to expand the program to more brands and reuse 60,000 jars. The company currently operates across Toronto and the Waterloo-Wellington region in Ontario.

“It’s been great to see more and more people get behind Circulr and the idea of reuse generally over the last few months,” says co-founder Tyler De Sousa. “We’re now supporting over 20 brands and collecting at over 20 retailers, comparing that to where we were a year ago really shows how quickly things are changing and how much we can accomplish in the future.”

Coca-Cola Canada Bottling

To reduce carbon emissions, Coca-Cola Canada Bottling is integrating six Volvo VNR Electric trucks this year into its iconic “Red Fleet” customer delivery routes throughout the Montreal area. It’s part of the company’s plan to reduce carbon emissions from direct sources and supplied energy by 46.2% by 2030.

“As we strive to become the leading beverage partner in Canada, we’ve made it our mission to put environmental sustainability at the heart of our business, which is why we’re extremely proud to have partnered with Volvo Trucks on this exciting initiative,” says Stephen du Toit, president and chief operating officer at Coca-Cola Canada Bottling. “We recognize we have a responsibility to effectively manage our environmental impact across the country and are continuously working to find innovative solutions to decrease the emissions from our fleet.”

The battery-electric fleet provides a range of up to 440 kilometres on a charge, making it well-suited for average daily round trips of 150 kilometres. The bottler has installed three 150 kW DC chargers with nine dispensers at its Montreal distribution centre to charge the fleet. It plans to incorporate additional battery-electric trucks into its fleet where it makes sense.

Conagra Brands Canada

More than a decade ago, Conagra launched its Zero Waste Champions program to recognize facilities within its operations that use environmentally responsible practices to avoid waste and reduce greenhouse gas emissions.

Conagra Brands Canada’s two Canadian manufacturing facilities – in Dresden, Ont. and Richmond, B.C. – have been recognized internally as Zero Waste Champions for diverting more than 90% of waste materials from landfills by using waste-reduction measures such as proper waste separation and recycling.

When an employee at the Dresden facility – which grows and packs nonGMO Aylmer Tomatoes – noticed there was considerable water loss in the section of the flumes that transport produce, he used salvaged scrap metal and valves to improve flow and reduce water spillage. This simple adjustment reduced water consumption by 33,000 gallons per day and 1.4 million gallons over Conagra’s fresh pack season.

All 17 of Conagra’s Zero Waste Champion facilities network wide “are leading the company’s efforts to nourish the planet and reduce waste at the source,” says Michael Fazio, Canadian head of sustainability at Conagra Brands Canada. In fiscal 2022, the facilities diverted more than 183,000 tons of waste.

“Our teams consistently strive to meet environmental challenges head on, underscoring Conagra’s commitment to nourishing and restoring the planet,” says Fazio.

Danone Canada

Danone Canada’s facility in Boucherville, Que. achieved Zero Waste to Landfill status at the end of 2022. The zero waste goal, an initiative for Danone’s manufacturing facilities in North America, involves a strong commitment to eliminating waste, not just treating it, by optimizing the choice and usage of materials.

According to Danone Canada’s definition of zero waste, less than 1% of non-hazardous waste is disposed to landfill and no hazardous waste is sent to landfill. In addition, incineration without energy recovery is prohibited (except for hazardous waste disposal as required by law). By following the s e criteria, the Boucherville facility is setting new company standards in terms of waste produced during its food and beverage production.

“At Danone, we are deeply committed to innovation, optimization and sustainability, especially when it comes to waste reduction and packaging circularity in our operations,” says Pascal Lachance, sustainability director at Danone Canada. “By achieving our Zero Waste to Landfill goal at our Boucherville plant, it demonstrates not only that commitment, but that we walk the talk when it comes to doing our part.”

Dutchman’s Gold

Canadian beekeepers are losing more than a quarter of their honeybee colonies each winter due to a combination of pesticides exposure, habitat loss and the effects of climate change. It is a significant loss, given that one-third of crops rely on honeybees and other pollinators.

Enter the Bee Friendly Promise, an initiative launched by Dutchman’s Gold to address this decline, raise awareness about the importance of honeybees and take action to support their well-being.

“We need honeybees to be healthy and thriving,” says Dutchman’s Gold co-owner Angela Van Alten-Ysseldyk, who, along with her husband in 2018, purchased the Carlisle, Ont.-based company founded by her father in 1981.

“Growing up on the Dutchman’s Gold honey farm taught me the importance of staying connected to farmers, beekeepers and biodiversity for a healthy honey crop,” she says.

The initiative aims to protect the supply chain, support local beekeepers, promote sustainable packaging and address the decline in honeybee populations. Actions include a virtual education series for retail partners and site tours for distributors and retailers. The Bee Friendly Promise seal will be included in the next production run of all Dutchman’s Gold products.

“Consumers want to know they’re consuming something that’s good for their body, but also something that’s good for the planet, too,” says Van Alten-Ysseldyk. “I think that really resonates.”

Eco Guardian

Eco Guardian has been producing organic and eco-friendly food packaging since 2004. With its latest launch, the Ontario-based company is taking on household paper to address growing environmental concerns over single-use paper products and deforestation.

Made from unbleached bamboo, the Bamboolia product line covers household paper products ranging from bath and facial tissues to paper towels and napkins.

“As a culture we have become accustomed to household paper being one way—white and fluffy, and at the cost of our forests,” says Swapnil Abrol, vice-president, special projects for Eco Guardian and founder of Bamboolia. Bamboo, by contrast, requires no replanting, grows 10 times faster than trees, and requires less water to support its growth and harvest. “We developed Bamboolia to prove that paper doesn’t need to come from trees, but rather can come from a super sustainable crop that grows like crazy and still produces a high-quality product,” explains Abrol. In addition to offering Canadian shoppers an alternative to tree-based household paper, Eco Guardian allocates a portion of proceeds from every Bamboolia item sold to various environmental efforts, including tree replanting in Canada.

Flashfood

Flashfood’s mission is to eliminate retail food waste by offering retailers and shoppers a simple and affordable way to feed families, not landfills. The app-based marketplace connects consumers to great discounts on high-quality groceries including fresh produce, meat, dairy and bakery items.

How does it work? Grocers do daily date checks, identify items for Flashfood, upload them to the app, and place the items in the Flashfood Zone. Shoppers browse and purchase the items through the app and pick up their orders in-store. Today, Flashfood operates in nearly 2,000 grocery stores throughout Canada and the United States. In 2022, Flashfood and Loblaw – its biggest partner in Canada – celebrated a milestone of 40 million pounds of food diverted, including more than seven million pounds of produce.

Eliminating food waste at the retail level by diverting it to dinner tables not only reduces harmful emissions at landfills, but it also addresses the connected problems of hunger and food insecurity. Flashfood also helps retailers recover lost profits and achieve their sustainability goals.

“Flashfood wouldn’t be here without our retail partners who hustle behind the scenes to make our platform and our mission possible,” says founder and CEO Josh Domingues. “Looking ahead, we’ve got our sights set on accessibility – being available in more places and at more stores with the goal of saving consumers money on groceries and rescuing millions more pounds of food from landfill.”

Freybe Gourmet Foods

Freybe Gourmet Foods achieved significant sustainability milestones in 2022 as part of its action plan to reduce emissions, electricity, packaging and food waste. Last year, Freybe successfully diverted 60% of its food waste from landfills by partnering with West Coast Reduction to convert the waste into animal feed and renewable energy.

Freybe also cut its water usage by 22.8K cubic metres, the equivalent of 640,000 showers, by upgrading its facilities with low-flow toilets and tap aerators as well as through changes to its salami production process. The company’s LED lighting improvements have saved 1.03 million KWH in electricity usage, while its eco-friendly packaging initiatives brought about an annual reduction of 96 kilograms in paper, 96 kilograms in plastic, and 2,260 kilograms in corrugate. Moreover, Freybe was recently approved for a FortisBC pilot project, which will significantly decrease its boiler emissions and repurpose captured carbon for soap and cleaning supplies.

This year, Freybe also plans to upgrade its wastewater treatment system and work with a smart recycle waste broker to further develop its waste diversion and management initiatives.

Greenhouse Juice Co.

Organic beverage company Greenhouse Juice Co.’s Fight Against Plastic and Microplastic Pollution initiative is driven by its commitment to the health of both its customers and the environment, according to co-founder and CEO Anthony Green.

“When I learned that the top two contributors to plastic pollution were beverage giants, it became clear to us that Greenhouse needed to take accountability and be a part of the solution,” says Green.

To combat this crisis, the company is taking innovative steps towards plastic-free packaging, including switching to recyclable aluminum caps and using post-consumer paper waste for its product labels. Greenhouse predicts these updates will prevent more than 100,000 kilograms of plastic waste from entering the environment within the next 12 months.

Additionally, Greenhouse is educating consumers through an online microsite linked via QR code to its new cap, which shares information about plastic pollution and the company’s goal of achieving a completely plastic-free supply chain. Greenhouse wants to inspire larger beverage businesses by setting aggressive sustainability goals and transparently communicating its progress and challenges. Greenhouse’s ultimate vision is to reduce its current plastic usage by more than 95% by the end of 2025 and implement a comprehensive closed-loop reuse program for its bottles.

Group Bel Canada

Since plant-based products are part of the solution to growing environmental challenges, Group Bel Canada has set a goal to offer a balanced range of fruit-and-plant-based and dairy products by 2030. It’s well on its way. In the past three years, the company has diversified its plant-based product offerings and has implemented measures to reduce its environmental impact.

With the construction of its new plant in Sorel-Tracy, Que., the company is prioritizing local production and avoiding shipping from Europe. About 90% of Group Bel Canada’s products are now produced in Canada. The plant is thermally insulated to be energy efficient, with air systems designed to allow for energy recovery, and its sustainable design is reducing its carbon footprint.

In collaboration with The Climate Fresk NGO, the company has established a training program to raise awareness of climate change. More than 80 employees have been trained.

“At Group Bel Canada, I feel that every day we get to live our mission to provide healthy and responsible snacks for all,” says Cristine Laforest, CEO of Group Bel Canada. “We have an opportunity to influence positive innovation, consumers’ eating habits and help take care of the planet at the same time. We have a responsibility as manufacturers to do our part to provide more sustainable solutions in this fast-changing world.”

Kootenay Co-op

“We work with our community’s needs, and values [are] at the heart of everything we do,” says Daniel Eisen, outreach co-ordinator for Kootenay Co-op. “Knowing how important and urgent the climate crisis is to our community and the lands we rely on, we knew that we had to act and place sustainability at the forefront of our operations.”

Recognizing the environmental impact of food waste in landfills, the community-owned grocer launched a program that sees safe-to-consume but unsaleable goods offered to staff or donated to local food banks. The program is estimated to now rescue thousands of kilos of food waste each year. Kootenay Co-op further minimizes food waste through its rigorous compost program, which gives members access to compost for home use or farming.

The B.C. grocer has also achieved a 15% reduction in plastic bag usage by introducing a discount for customers who bring their own containers to refill bulk items, while the installation of three nylon reusable pallet wraps has helped the store make additional strides in reducing its single-use plastics. Furthermore, Kootenay Co-op has tackled energy efficiency through the installation of electric vehicle charging stations, e-bike charging stations, and a heating system that operates without external electrical or hydro input.

Longo’s

Longo’s stated purpose is “fuelling happier and healthier lives,” something that guides everything the 67-year-old grocery chain does, including its approach to sustainability. Recognizing the significant environmental impact grocery stores can have on the planet – through operations and supply chain – Longo’s has committed to combat those effects through actions such as reducing greenhouse gas emissions (GHG). In fact, in 2022, Longo’s saw a 45% reduction in GHG emissions from 2020 – a feat largely achieved through refrigerant conversions.

Longo’s determined the most significant source of its scope 1 (direct GHG emissions released from its operations) were from refrigerant leaks. Commonly used hydrofluorocarbon refrigerants, for instance, are potent GHG that trap thousands of times more heat in the atmosphere than carbon dioxide. So, to reduce its climate impact, all new Longo’s stores since 2012 have been built using a CO2 refrigerant system with an ultra-low global warming potential (GWP).

“Refrigerant leaks are one of our main sources of greenhouse gas emissions and represent a risk as leaks are unpredictable. By converting to a lower global warming potential refrigerant, we have an opportunity of reducing the GWP by 65%, further reducing the climate impact of our refrigeration systems,” explains Dave Mastroieni, vice-president, central procurement and facility management at Longo’s.

To date, 44% of Longo’s locations use a CO2 system and in its 2022 Sustainability Report, Longo’s made the commitment that 100% of its stores (currently it has 37) will use refrigerants with lower GWP or a natural refrigerant system by 2030.

Nestlé Canada

As the world’s largest producer of food and beverage, Nestlé recognizes it plays a significant role in creating a more sustainable future. At the core of this journey is the company’s Net Zero Roadmap, which launched in 2020 and aims to drive down Nestlé’s greenhouse gas emissions and get to net zero by 2050.

Our net zero commitment is at the core of our sustainability journey. Even as we grow, we will continue to endeavour to drive down our emissions and get to net zero,” says Catherine O’Brien, senior vice-president, corporate affairs, regulatory, government relations and sustainability. “Our commitment is guided by our desire to help protect, renew and restore the environment, strengthen communities and operate responsibly.”

Nestlé is reimagining all aspects of the business, from the ingredients and packaging it uses, to how it makes and transports products, to how it supports local communities. For example, the Nestlé Cocoa Plan addresses complex challenges faced by farming communities – focused on the Ivory Coast – such as training and educating local farmers.

Nestlé’s four core confectionery products – KitKat, Aero, Coffee Crisp and Smarties – are made using 100% sustainable cocoa certified by Rainforest Alliance. In 2022, Nescafé announced its plan to help make coffee farming more sustainable through the Nescafé Plan 2030, which includes helping transition coffee farmers to regenerative agriculture.

Nestlé is also on a journey to make all of its packaging recyclable or reusable by 2025 and to reduce its use of virgin plastics by one-third in the same period. Nestlé’s popular Smarties brand uses paper packaging that is responsibly sourced and certified by third-party organizations including the Forest Stewardship Council (FSC) and Sustainable Forestry Initiative (SFI).

Pattison Food Group

B.C.’s Pattison Food Group (PFG) – whose retail banners include Save-On-Foods, Buy-Low Foods, Urban Fare and others – has a long track record of environmental leadership. The company is making a positive impact in myriad ways including its ongoing efforts to achieve zero waste by reducing its operational waste to prevent surplus plastics, packaging and food waste being sent to landfill.

PFG stores across Western Canada currently divert more than 90% of unsaleable food to community organizations, food banks, family farms, and to make compost – putting edible, surplus food to its highest use. When building new stores, the company uses smart tech designed to reduce energy consumption. At the company’s largest banner, Save-On-Foods, LED lighting conversions are reducing energy consumption by more than 30% year-over-year, while refrigeration conversions are reducing environmental impact.

Along its sustainability journey, the company has forged strong partnerships with several organizations, among them: local food banks, Canadian Centre for Food Integrity, Food Mesh, Ocean Wise, Mercy for Animals and Call2Recycle. The latter group named Save-On-Foods its 2022 Leader in Sustainability for helping divert nearly 4.4 million kilograms of batteries from landfills last year.

“Our commitment to sustainability stems from how much our customers and team members care about building a greener future,” says Heidi Ferriman, senior vice-president of people and corporate affairs. “We are proud of the partnerships we’ve formed with local organizations and also of the commitment we see from our teams – both [of] which have enabled us to positively impact millions of Canadians through our sustainability efforts.”

Rabba Fine Foods

Rabba Fine Foods is developing solar energy systems that will substantially reduce its carbon footprint. When completed, the solar energy systems will generate more than 1.5 million kWh of electricity annually, offsetting most of the electricity requirements for the retailer’s Mississauga, Ont. distribution facilities.

The project, conducted in collaboration with Green Integrations and Star Energy Solutions, will reduce the company’s reliance on traditional electricity generation and will ensure the products Rabba sells have been delivered using renewable energy.

“The decision to invest in environmental initiatives like solar panels is one of the many ways in which Rabba Fine Foods is working to become a more sustainable business,” says Rick Rabba, the company’s president. “We take pride in the fact that we are playing our part to make positive change in our industry.”

The company’s solar energy project is an extension of retrofit and upgrade projects started several years ago by Rabba that include the elimination of older electrical fixtures in favour of more energy-efficient options. Rabba is also phasing in digital smart labels, which will eliminate the need for label printing, minimizing the grocer’s reliance on paper printing in stores.

Second Harvest

Canada’s largest food rescue organization, Second Harvest, has been at the forefront of the fight against climate change since 1985. Its decades-long efforts took on even greater significance over the past year as demand for charitable food services increased by 134%, according to a December 2022 survey.

“Food rescue connects great, healthy food to people who need it,” explains Lori Nikkel, chief executive officer at Second Harvest. “This was more important than ever in 2023 due to the rising cost of food, the increase in food insecure Canadians and the very real detrimental damage food waste in landfill is having on our climate.”

In 2022 alone, Second Harvest rescued and redistributed 53.3 million pounds of food to more than 3,700 non-profit organizations, reaching more than 4.3 million Canadians facing food insecurity. Second Harvest’s work has also prevented the release of approximately 162 million pounds of greenhouse gas emissions and conserved 31.2 billion litres of water. Going forward, Second Harvest aims to further increase its impact by redistributing 75% more healthy perishable food in the next three years, amounting to more than 72 million pounds of nutritious food redirected to Canadians in need.

Wonderful Pistachios

Since 2019, Wonderful Pistachios, one of the largest nut processors in North America, has been working to transition its operations to 100% renewable electricity.

“We believe that agriculture must be part of the solution to address greenhouse gas emissions globally,” says Mike Hohmann, Wonderful Pistachios’ executive vice-president and chief financial officer. Aiming to meet its renewable electricity goal by 2025, Wonderful Pistachios has invested more than US$130 million to install major solar projects across its facilities in California’s San Joaquin Valley, the largest of which spans more than 100 acres. These solar facilities now deliver 75% of Wonderful’s electricity needs for pistachio and almond processing, generating emission reductions comparable to eliminating 4,000 gas-fuelled vehicles from the road each year.

Additionally, the company has converted 100% of its pistachio farming vehicles from fossil diesel to renewable diesel, amounting to an estimated reduction of 9,800 metric tonnes of greenhouse gas emissions in 2022.

“Wonderful Pistachios’ energy transformation initiative has been successful because it engages farm vehicle operators, electricians, facility teams, and procurement professionals,” says Hohmann. “We’re able to enact change across our organization at every stage of the process."

Canadian Grocer’s Impact Awards will be returning in 2024. Look out for our call for nominations in the New Year.

Winners of the 2023 Impact Awards were first featured in Canadian Grocer’s August issue.