The Innovators: How Uptaste is redefining in-store sampling

Is this the end of traditional product sampling as we know it? That day is coming, according to Uptaste.

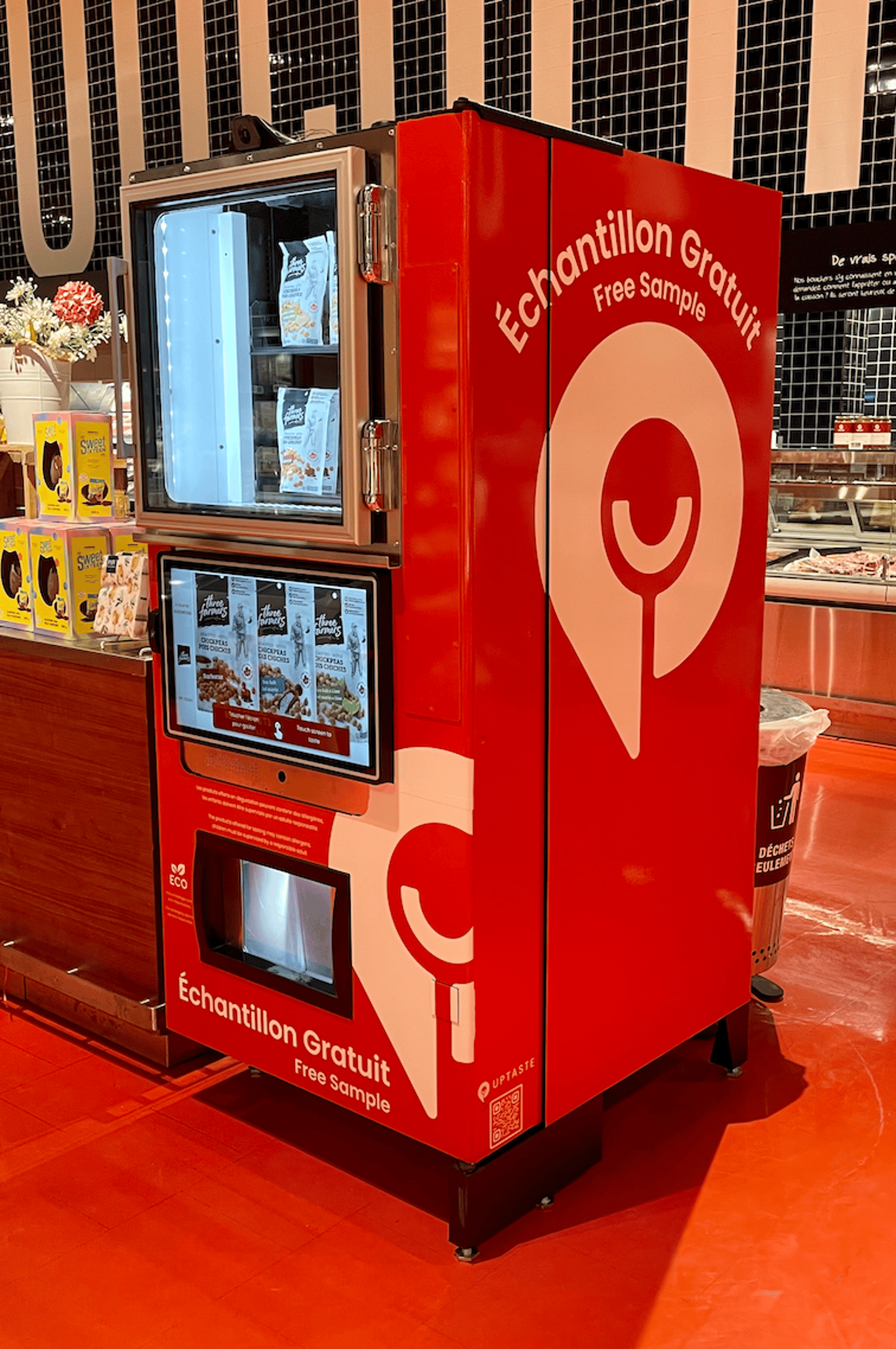

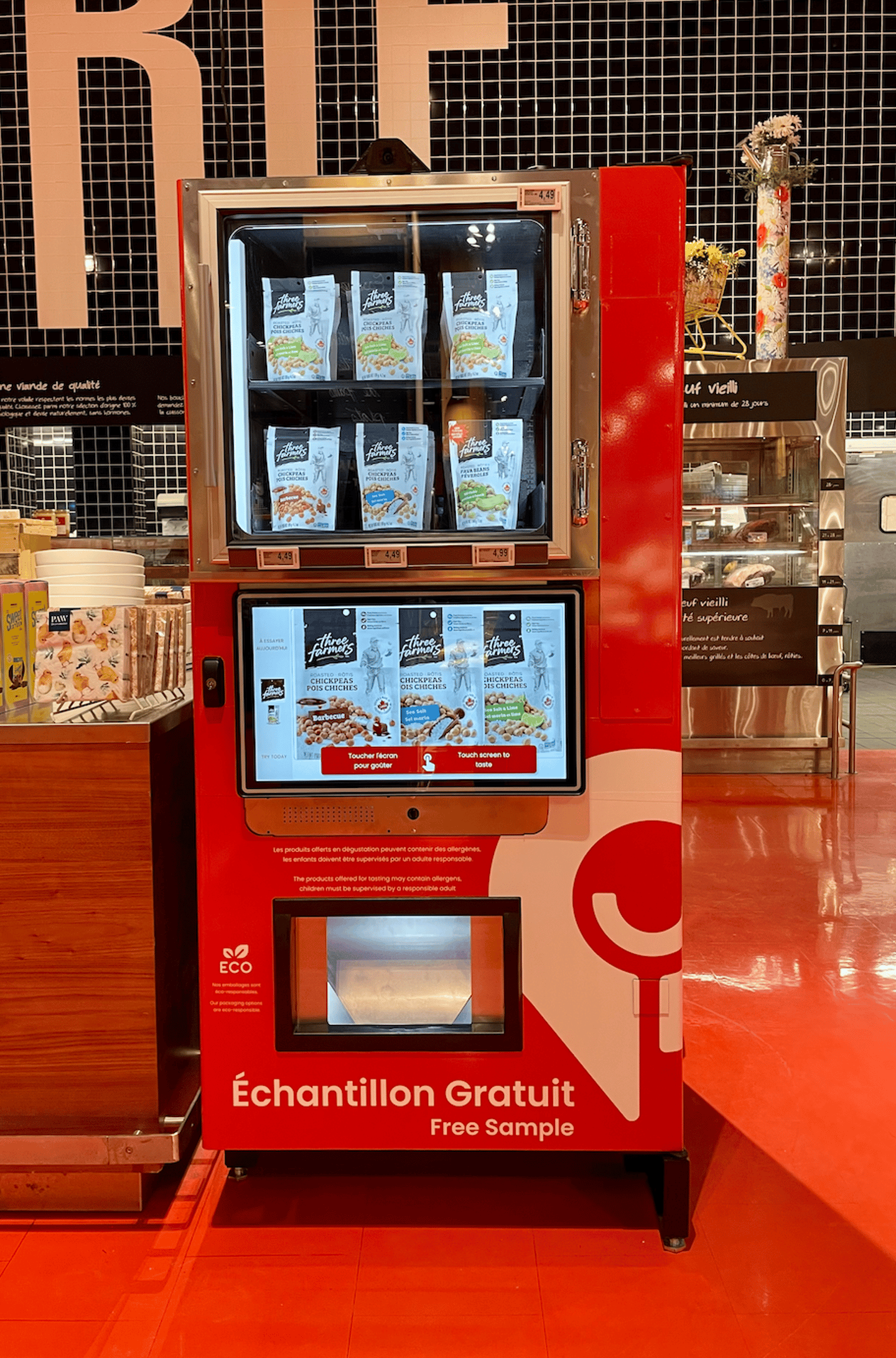

The Montreal-based company has developed an automated sampling machine, “the Uptaster,” that easily puts food and beverage samples into the hands of consumers. Shoppers simply click on an interactive screen to receive a sample from a temperature-controlled machine. If they like it, they can grab a full size (or other brand SKUs) to purchase from the machine. The screen also asks for feedback, so consumers can vote thumbs up, thumbs down, or neutral, and they’re invited to take a selfie that’s shared with the brand.

READ: Grocery shoppers are ready for samples again

Uptasters are now set up at Avril Laval, Provigo Boucherville, La Moisson and four IGA stores in the Montreal region, with more than 80 participating brands to date including Prana, Chocxo, NaturSource and GoGo Quinoa. Uptaste plans to expand across Quebec and Ontario, and eventually across the country.

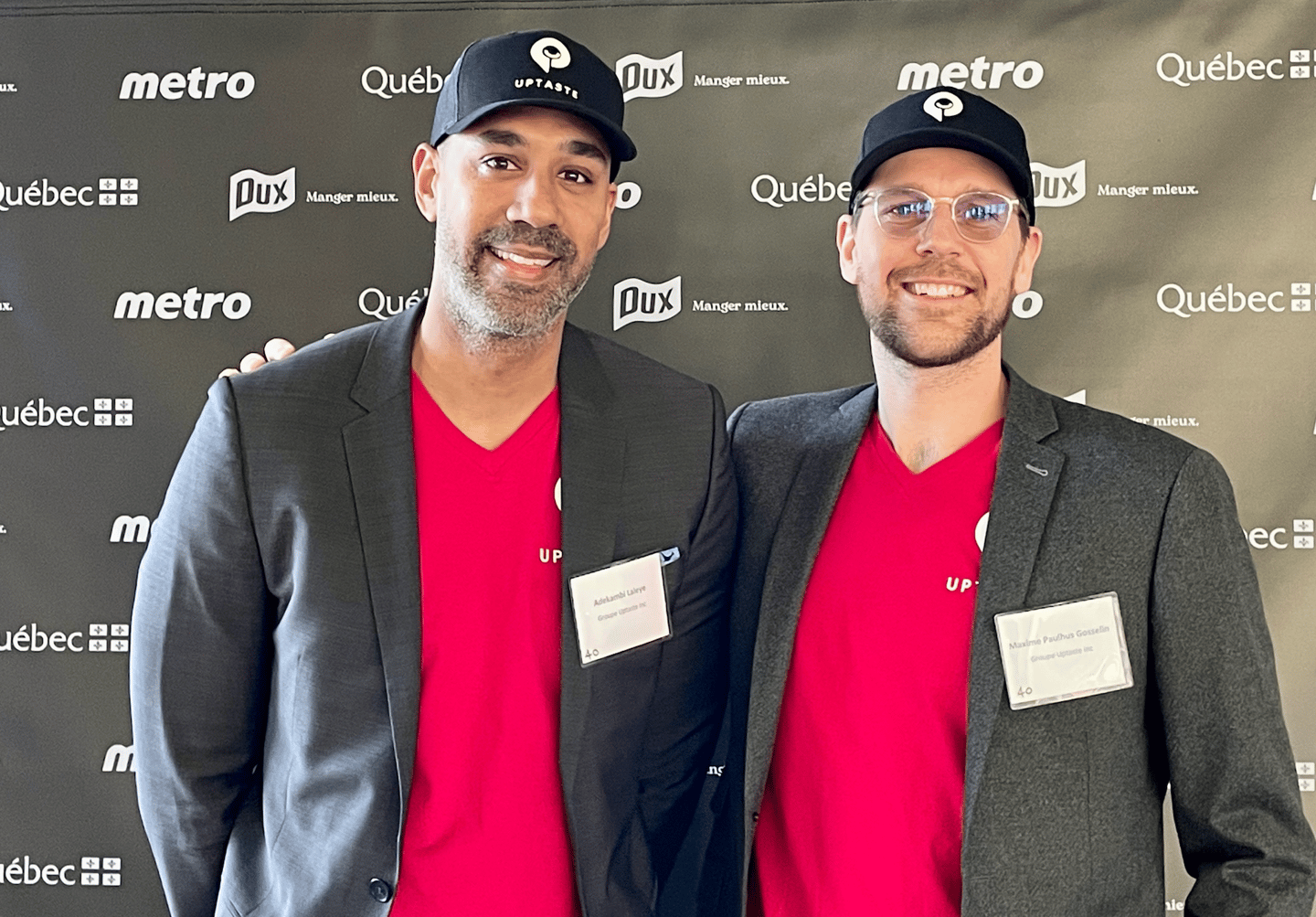

In this Q&A, co-founder Adekambi Laleye talks about how Uptaste got its start; how automated sampling benefits brands, retailers and shoppers alike; and why the company believes this is the future of in-store product sampling.

How did you come to co-found Uptaste?

I met my best friend and now business partner Maxime Paulhus Gosselin (Max) on the basketball court back in 2003. We both went away to school in the States – he went to Davidson College and I went to the University of Buffalo – and we stayed in touch. In 2012, Maxime was running his parent’s import/export business and launched a cheese called Old Amsterdam in Canada. Every weekend he would go into grocery stores and do in-person sampling and grew his demo team to 15. At night, we would often work together on our businesses – I was running my own digital agency at the time – and one night he said there must be a better way to serve consumers and retailers. Finding, training and paying staff were pain points even back then… He actually drew on a napkin a machine that would cut up cheese and hand it to consumers. I said, ‘This is a fantastic idea but you’re busy and I’m busy; it’s not the right time [to start a new business].’

Fast forward to 2021… We had decided we would go into business together. On a trip to Costa Rica, we threw a hundred ideas at the wall and nothing really fired us up. One day, Maxime just looked at me and said, ‘What about in-store samples?’ It was COVID, so sampling went from a booming industry to zero overnight. But everyone still understood that sampling works. So, it was a perfect time to disrupt it and we knew from research that sampling drives loyalty and sales.

We came back from Costa Rica and built the first Uptaste machine in Max’s father’s garage. After a few iterations and observing consumer interactions with the machines in stores, we developed our latest version. Last year alone, we had more than 60,000 samples taken from our machines and this year we’re on pace to do well over 600,000 samples.

READ: Higher tech in the grocery store

How does Uptaste compare to a traditional sampling program?

In a traditional tasting, you might have a great brand ambassador or a not-so-great brand ambassador. From a consistency standpoint, [with Uptaste], a video plays on loop so the consumer gets the same message delivered to them every time. And a lot of feedback we’ve received is that it's hard to find good staff and keep them. Chances are the person you’re hiring to promote your product doesn’t care about your product, doesn’t know about your product, and might not even like your product. So, what they share with the consumer might be the wrong information or it might be something you don’t want them to share.

The product that comes out of the machine in the exact same every time: the sizing, the taste and the temperature you want your product to be tasted at. In addition, we’re able to offer samples 24/7 or whenever stores are open. So, brands can reach consumers who grocery shop at 3 p.m. on a Tuesday, for example, whereas typically that consumer would not see a sample in store. Traditionally, you might only have a brand ambassador on Friday evenings, or the 10 a.m. to 4 p.m. window on Saturdays and Sundays.

READ: Negative in-store experiences could cost food, retail brands

What’s your response to those who might think automated sampling is just one more area of our lives where we’re losing the human touch?

Our target market is innovators and there’s not an age for innovators. You can be an innovator at eight years old or 90 – it’s really the mindset of a person who is looking for something new and willing to try something new.

What are your growth plans?

The plan is to have 23 machines in the Montreal region by mid-summer and continue to grow in Montreal and Quebec with 100 to 150 machines the following year in this region. From there, we’ll look to the Ontario market and then across Canada, with the goal of having 1,500 to 2,000 machines in the next couple of years. We are looking to partner with retailers that are willing to take risks and are passionate about their consumers and innovation… You can be status quo and move the needle slightly every single year. But if you want to take a leap and push that edge, then you have to be willing to take a risk and be passionate about innovation.

READ: Global grocery: News and ideas from the world of food retail

Do you see an eventual end for human samplers and sampling will all be automated?

Yes. The goal in our roadmap is to expand into frozen samples, so we’ll be able to do ice cream and popsicles, for example. We also want to sample hot items, whether it’s chicken wings or hot teas and coffees. So absolutely, when we cover those next two verticals, we’ll be able to replace in-store sampling 100%. And for us, it’s taking those jobs that are hard to fill and creating new jobs, for example, people delivering samples to the stores for us, or client success reps, or co-packers in our facility. So, it’s not removing jobs from the market at all. It’s creating new jobs in other areas.

There’s no shortage of innovation happening in the food industry. From fresh retail concepts to avant-garde products, Canadian Grocer is putting the spotlight on the people and businesses moving the industry forward in our new series, The Innovators. Have a pitch? Send your submissions to digital editor Jillian Morgan.