Second Harvest talks results of two-year food waste project

A project with 20 Canadian food manufacturers, including Maple Leaf Foods, Nature’s Touch and Bimbo Canada, and funded by Walmart Foundation, is revealing how food waste can be practically and affordably reduced at the source.

According to Second Harvest, nearly 60% of food produced for Canadians is lost or wasted every year. Grocers have been working on reducing the expired or imperfect food they throw away. But where the industry can make the biggest impact is further up the food chain. Almost 50% of lost or wasted food is occurring during manufacturing and processing – 47% to be exact, the equivalent of 16.77 million metric tonnes.

Second Harvest’s recently completed two-year “Food Loss and Waste Implementation Project” saw Enviro-Stewards and Anthesis Provision advise 20 manufacturers. Anthesis Provision provided change management and goal-setting consulting, while Enviro-Stewards implemented and verified the performance of food loss prevention measures.

“There has been this belief that such measures would cost a lot of money and manufacturers wouldn’t see a ROI for years, if not decades,” Bruce Taylor, president of Enviro-Stewards, tells Canadian Grocer. “But small, inexpensive measures can have a huge impact, and have a ROI on your business in just a few months.”

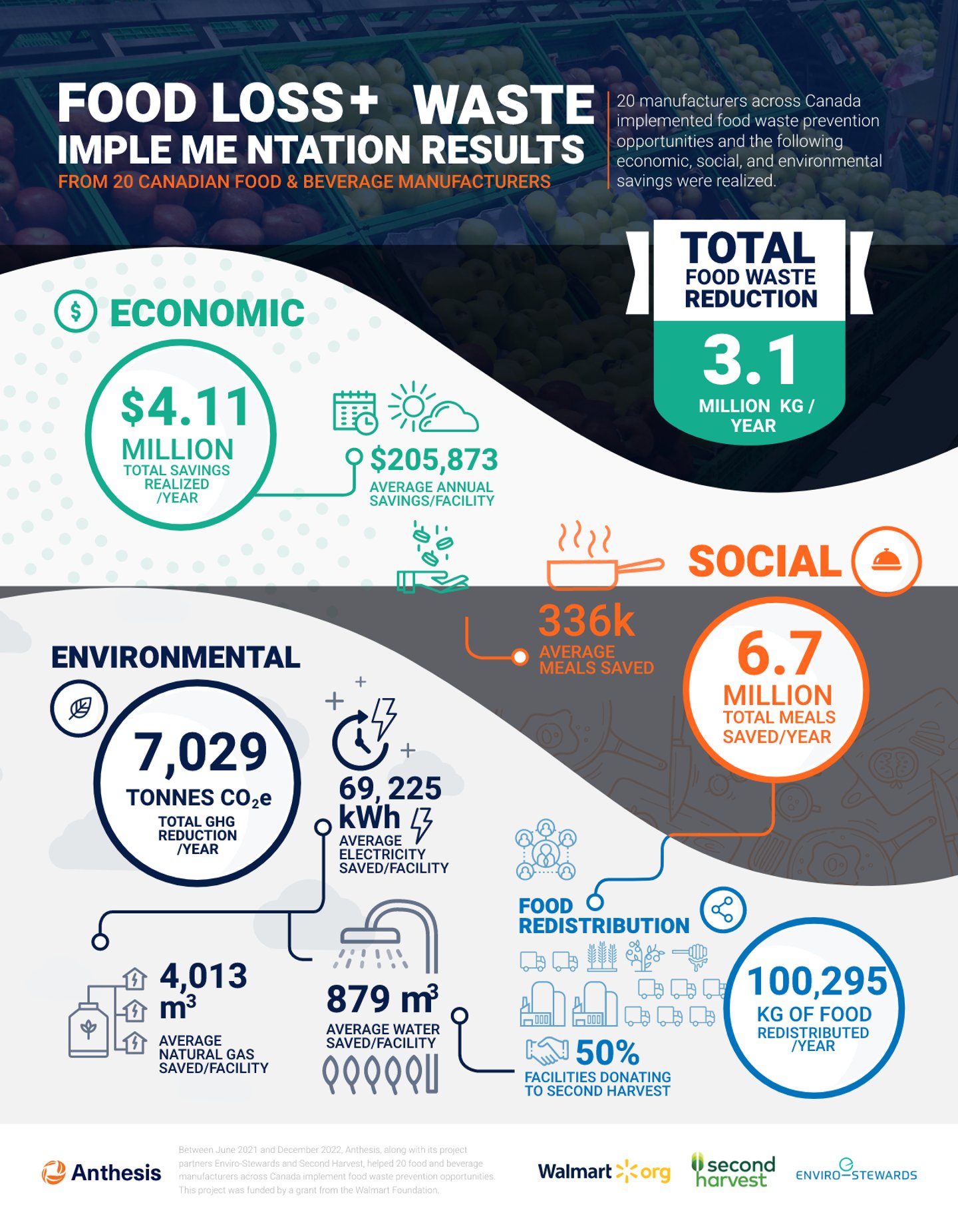

In fact, the manufacturers made a positive impact environmentally, socially and economically.

Collectively, they prevented 3,109,433 kg/year of food loss on an annual basis. In addition, about 100,295 kg of food was redistributed, with 50% of that being done so through Second Harvest, a set-up these companies didn’t have in place before.

But the rest of it was prevented from being lost or wasted in the first place by identifying and troubleshooting manufacturing inefficiencies. For instance, Nature’s Touch, a brand of frozen fruit and vegetables, saved 8,838 kg of blueberries a year by installing a metal plate over a gap between sections of a processing line where fruit was falling to the ground.

The cost of this low-tech solution? $1,500. The annual cost savings? $28,695.

By reducing food waste through such measures and improving efficiencies, the companies saved a combined 7,029 tonnes of greenhouse gas emissions. Each of the 20 manufacturing facilities reduced their use of water by an average of 879 m3 , natural gas by 4,013 m3 and electricity by 69,225 kWh per year.

The economic savings are equally impressive. Each facility saved an average of $205,800 per year in large part by retaining food that was previously being lost or wasted. Together, that amounts to $4.11 million in annual savings (and enough food for 6.7 million meals).

Taylor says the producers were seeing return on investments at manufacturing of 12 months or less.

“Manufacturers have been looking at how to dispose of their food waste efficiently, and often think composters, digesters or dumpsters,” says Taylor. “It may be the cheapest option on the surface. But that doesn't factor in the purchase cost of that food in the dumpster, the energy costs to produce it and having to continually purchase more ingredients than necessary because of the waste.”

Manufacturers need a new paradigm in thinking about food waste, he says.

“Instead, manufacturers need to ask, ‘How do we reduce the food being wasted in the first place?’” says Taylor. “That is not only a better play for society and the environment, but it also makes financial sense, because you’re not having to repurchase the lost food and everything that went into the food.”

In terms of food redistribution efforts, Second Harvest CEO Lori Nikkel says the project surpassed its food-rescue goal by 7%.

“That this was achieved during staffing shortages, employee turnover and supply chain issues caused by the pandemic was huge, and a testament to these companies and the commitment from management to frontline workers,” Nikkel tells Canadian Grocer.

There is “no silver bullet” in terms of coming up with food redistribution efforts, she says, because “different businesses require different solutions.” But Nikkel says what every business does need to do is measure the amount of food they are wasting or losing.

“You don’t know what you don’t know. And so if you measure it, you have a better chance of mitigating it.”